Download C,hex file here with design:http://www.4shared.com/rar/2dZJ5rlL/lcd3wire.html?

Electronics Fusions

Thursday, 29 August 2013

Friday, 28 June 2013

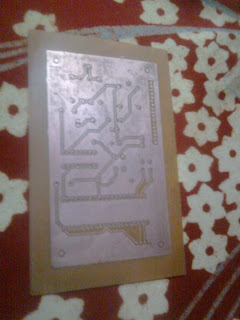

Making PCB using Toner transfer method

Making a PCB is very simple; it does not consume a lot of time and

the results look professional. After reading this How-To and watching

the step by step video, you will be able to make your own PCB in your

workshop using just a few inexpensive materials.

Many people use protoboard and point-to-point wire everything, but needing multiple copies of the same circuit is the reason that forces many away from using protoboard. After making your first circuit board, you might not point-to-point wire anything again!

For your first circuit board, one goal is to keep the circuit single sided so you can etch using single sided copper clad. This will allow you to gain some experience before moving on to double-sided

Here is a list of materials you will need to produce a single-sided board. With the exception of the copper clad and PCB drills, everything on this list is easily obtained at your local store.

1.Copper clad

2.FeCl3 solution or powdered form for etching

3.Laser printer

4.Drill machine

5.PCB designing software.

I bought copper clad for rs 60 from Lajpat Rai market,Size 1sq ft.just go to any pcb shop and ask for copper clad.

Laser printers are easy available from your near by internet cafe or photostat shop.Make sure to ask them that the printer they are using is Laser or inkjet.Any printer other than Laser cannot do the task.So a laser printer is must.

Drill machine is also available at lajpat rai from shop no 200.it cost me 90 rs and its 1mm bead for 20 rs extra.

For PCB designing any suitable PCB software can be used.I did mine in ORCAD.

Now what about FeCl3?I got it from a friend of my pursuing graduate degree.I ask him and he did brought it from his lab.So just go and find your undergraduate friend.

Now, here is how you do it:

Print the bottom side layer on a piece of paper from a high quality magazine or photopaper. Use one actual page from the magazine, the thicker and shinier the magazine paper the better, but do not use the cover. You must use a laser printer, not an inkjet. If your printer uses ink cartridges and not toner cartridges, it will not work. If you do not have a laser printer, you can work around this by printing to white paper and using a photocopier set to the darkest setting to copy the layout to the magazine paper.

I used a photo paper cost only rs 10 to print the circuit.Almost every stationary have it.

Magazine pages are used because they work well, and they are cheap! The reason they work is because the paper is very glossy and the toner does not adhere well to the glossy pages. The printing used on the magazine page is ink and it does not come off, but toner does. Toner is actually a plastic polymer, and different toners may yield varied results

Very carefully, remove the copper clad from the packaging. Do not touch the copper surface for the same reason as above. You can cut the copper clad to size using a tin snip if needed. Use the Scotch Brite scrubbing pad to gently buff the surface (Scotch Brite is a popular brand of of plastic scrubbing pad meant to emulate steel wool). Do not use steel wool because it will embed steel into the copper. Clean off the residual dust with a slightly damp paper towel. Use a kitchen scrubber or a fine sandpaper and sand the copper. Do not overdo it.Clean the surface with a cloth. Do not touch the surface once the cleaning is done.

Now that the board and the print are ready, switch on your clothes iron to the maximum heat and leave it for a minute or two.Align the printed paper on the copper board with the printed side over the board.Applying a bit of pressure, carefully move the iron on the paper for 2 - 3 minutes.If you have long lines in your PCB, they tend to not get transfered completely.

Bolster the lines on your copper board.To bolster the line, you can trace that line with a sharpie or a paint pen(works better). if you have a black electrical tape, you can use that as well. Cut it really thin(as thick as the line) and cover the line with the tape.

Etching Process

Drop the board into water and carefully peel off the paper and you should see the print on the board. If the paper does not peel off easily, remove it by rubbing it slightly.Prepare the etching solution with FeCl3 and water in a ratio of 150ml with 50g of FeCl3.Gloves and eye protection are recommended!Drop the board into the solution and wait for a couple of seconds.When the fine tracks are clearly visible and the unwanted copper removed, take the board out and clean it in water.

Place the board face up in the STRIP tray, and coat it with resist stripper. This may be in a bottle or in a 'shoepolish' dispenser. Rub in the chemical first with the soft sponge, then with with a plastic scrub pad. The green resist should come off, revealing copper underneath. Make sure -all- of the resist is removed, as it smells very bad when it gets hot (when soldering.) If there is no stripper, you can just scrub it off with a green scrub pad. If the stripper came from a bottle, pour it back in. Rinse off the board and tray.

Get start with the drill machine and place your components.

Get start with the drill machine and place your components.

Now your own professional PCB is ready to use.

Many people use protoboard and point-to-point wire everything, but needing multiple copies of the same circuit is the reason that forces many away from using protoboard. After making your first circuit board, you might not point-to-point wire anything again!

For your first circuit board, one goal is to keep the circuit single sided so you can etch using single sided copper clad. This will allow you to gain some experience before moving on to double-sided

Here is a list of materials you will need to produce a single-sided board. With the exception of the copper clad and PCB drills, everything on this list is easily obtained at your local store.

1.Copper clad

2.FeCl3 solution or powdered form for etching

3.Laser printer

4.Drill machine

5.PCB designing software.

I bought copper clad for rs 60 from Lajpat Rai market,Size 1sq ft.just go to any pcb shop and ask for copper clad.

Laser printers are easy available from your near by internet cafe or photostat shop.Make sure to ask them that the printer they are using is Laser or inkjet.Any printer other than Laser cannot do the task.So a laser printer is must.

Drill machine is also available at lajpat rai from shop no 200.it cost me 90 rs and its 1mm bead for 20 rs extra.

For PCB designing any suitable PCB software can be used.I did mine in ORCAD.

Now what about FeCl3?I got it from a friend of my pursuing graduate degree.I ask him and he did brought it from his lab.So just go and find your undergraduate friend.

Now, here is how you do it:

Print the bottom side layer on a piece of paper from a high quality magazine or photopaper. Use one actual page from the magazine, the thicker and shinier the magazine paper the better, but do not use the cover. You must use a laser printer, not an inkjet. If your printer uses ink cartridges and not toner cartridges, it will not work. If you do not have a laser printer, you can work around this by printing to white paper and using a photocopier set to the darkest setting to copy the layout to the magazine paper.

I used a photo paper cost only rs 10 to print the circuit.Almost every stationary have it.

Magazine pages are used because they work well, and they are cheap! The reason they work is because the paper is very glossy and the toner does not adhere well to the glossy pages. The printing used on the magazine page is ink and it does not come off, but toner does. Toner is actually a plastic polymer, and different toners may yield varied results

Very carefully, remove the copper clad from the packaging. Do not touch the copper surface for the same reason as above. You can cut the copper clad to size using a tin snip if needed. Use the Scotch Brite scrubbing pad to gently buff the surface (Scotch Brite is a popular brand of of plastic scrubbing pad meant to emulate steel wool). Do not use steel wool because it will embed steel into the copper. Clean off the residual dust with a slightly damp paper towel. Use a kitchen scrubber or a fine sandpaper and sand the copper. Do not overdo it.Clean the surface with a cloth. Do not touch the surface once the cleaning is done.

Now that the board and the print are ready, switch on your clothes iron to the maximum heat and leave it for a minute or two.Align the printed paper on the copper board with the printed side over the board.Applying a bit of pressure, carefully move the iron on the paper for 2 - 3 minutes.If you have long lines in your PCB, they tend to not get transfered completely.

Bolster the lines on your copper board.To bolster the line, you can trace that line with a sharpie or a paint pen(works better). if you have a black electrical tape, you can use that as well. Cut it really thin(as thick as the line) and cover the line with the tape.

Etching Process

Drop the board into water and carefully peel off the paper and you should see the print on the board. If the paper does not peel off easily, remove it by rubbing it slightly.Prepare the etching solution with FeCl3 and water in a ratio of 150ml with 50g of FeCl3.Gloves and eye protection are recommended!Drop the board into the solution and wait for a couple of seconds.When the fine tracks are clearly visible and the unwanted copper removed, take the board out and clean it in water.

Place the board face up in the STRIP tray, and coat it with resist stripper. This may be in a bottle or in a 'shoepolish' dispenser. Rub in the chemical first with the soft sponge, then with with a plastic scrub pad. The green resist should come off, revealing copper underneath. Make sure -all- of the resist is removed, as it smells very bad when it gets hot (when soldering.) If there is no stripper, you can just scrub it off with a green scrub pad. If the stripper came from a bottle, pour it back in. Rinse off the board and tray.

Get start with the drill machine and place your components.

Get start with the drill machine and place your components.Now your own professional PCB is ready to use.

Tuesday, 26 March 2013

8051 BASED STOPWATCH

The project uses seven segment displays and 89S51 controller to control the stopwatch.The stopwatch is enabled to count from 0 to 99.After 99 the watch toggles to 00.A nice start for beginners.Go and have some fun with programming and hardware.C program and design file are attached below.

DOWNLOAD:C PROGRAM AND DESIGN FILE

DOWNLOAD:C PROGRAM AND DESIGN FILE

Bidirectional Visitor Counter

The circuit consist of very basic components like seven segments,8051 microcontroller and buttons can be replaced by IR sensor circuits.Button 1 is used to increment the counter while button 2 decrements the counter.The counter shows an increment up to 9.This project will be a very good start for begineers in programming.Just assemble the circuit and amaze your friends.Coding and design file of the project is attached below.

DOWNLOAD:C PROGRAM AND DESIGN FILE

DOWNLOAD:C PROGRAM AND DESIGN FILE

8051 Based Wind Turbine

A 8051 based wind

turbine model consist of a moving rotor assembly consisting of a DC motor including the blades for

converting wind energy to low speed rotational energy. The generator component

includes the electrical generator, the control electronics, and most likely a gearbox

(e.g. planetary gearbox, adjustable-speed drive or continuously variable

transmission) component for converting the low speed incoming rotation to high

speed rotation suitable for generating electricity.

The whole generator system is mounted on a stepper motor configuration which

enables the system to move 180 ͦ towards

left and 180 ͦ towards right direction. This

enables the system to move 360 ͦ and

choose the direction of the wind anytime. This eliminates the dependency of

wind turbine on the direction of wind.

The system is connected with a controlling keypad to move the stepper motor in desired

direction. At the base of the turbine tower is a energy storing system made of resistors and capacitors to store

the AC voltage produced during the rotation of turbine blades. The capacitor stores the fluctuating

voltage and converts it into constant voltage supply to drive LED or other kind

of load.

An LCD is

provided along with keypad to display the condition of wind speed depending on

the speed of the moving blades. The LCD also displays the degree at which the

turbine system mounted on stepper motor is moving.

The system is connected with an Atmel 89S52 microcontroller which

controls and manages the working of whole assembly including stepper motor,

keypad and LCD display.

Key features of this project are:

Ø

A DC motor is used to generate the power from

moving wind.

Ø

Capability of turbine to rotate in 360 ͦ direction to choose the optimum direction

of flowing wind.

Ø

Controlling of system using a keypad present at

the base of the tower.

Ø

Uses a LCD to display the angle rotated by the

turbine assembly through stepper motor.

Ø

The power is stored in a capacitor circuit to

convert the fluctuating voltage into dc voltage.

Ø

8051 based turbine system to control the turbine

mechanism and stepper motor controlling mechanism.

Ø

The microcontroller and LCD works on a +5V

supply.

Thursday, 17 January 2013

Low cost Audio amplifier using LM386

All that is needed to build an audio amp are a few external components most of which are decoupling capacitors. It is well suited to low power applications

and runs just fine on a 9 volt battery or any voltage supply from 4-12

volts. It has a low quiescent current drain of only 4mA so it won’t kill

a battery right away if you leave it on and idle. The gain is

internally set to 20 but the addition of an external resistor

and capacitor between pins 1 and 8 will increase the gain to any value

from 20 to 200. An increase in bass frequency can be facilitated by

adding a 10K resistor and .033 uf capacitor in series between pins 1 and

5.

Sunday, 25 November 2012

Multilevel Car Parking System

Automatic multistoried car parking system helps to minimize the car

parking area. In the modern world, where parking-space has become a very big

problem and in the era of miniaturization, it is become a very crucial

necessity to avoid the wastage of space in modern, big companies and apartments

etc.

A display is provided at the ground floor which is basically a counter that displays number of cars in each floor. It informs whether the floors are fully filled with the cars or is it having place in a particular floor or not. There is facility of lift to carry the car to up and down. Movement of Lift is controlled by stepper motor. An indicator with a green and red LED is kept in all the floors to indicate whether the lift is busy or is it ready to take the car up or down. If the red LED glows that means the lift is already engaged and the person has to wait for the green LED to glow. In this project we have provided three floors of a building for car parking. Maximum storage capacity of each floor is given as ten. Storage capacity can be changed according to the requirement.

A display is provided at the ground floor which is basically a counter that displays number of cars in each floor. It informs whether the floors are fully filled with the cars or is it having place in a particular floor or not. There is facility of lift to carry the car to up and down. Movement of Lift is controlled by stepper motor. An indicator with a green and red LED is kept in all the floors to indicate whether the lift is busy or is it ready to take the car up or down. If the red LED glows that means the lift is already engaged and the person has to wait for the green LED to glow. In this project we have provided three floors of a building for car parking. Maximum storage capacity of each floor is given as ten. Storage capacity can be changed according to the requirement.

Any one can enter to first or second floor. The

third floor in this model is for VIP’s only. Therefore when VIP’s are to be

entering they are expected to enter their password and they will be taken to

the third reserved floor. The password will be of 4 digits. The processor

checks for the password entered and if it is found to be wrong, a siren is

heard. So when a password is entered, the processor checks for it and it is

compared with right password. It indicates whether it is the correct one or

not.

When the car enters the lift, the LDR detects

its presence and sends a signal to glow RED LED indicating that the lift is

busy. It also sends a signal to motor which makes the motor to rotate. After

RED LED glows the lift will take the person and the car up to the floor where

the space for parking is available. (For VIP it will be the third floor). When

the lift reaches the first floor, the processor compares the filled amount

to that of the already fed capacity of that floor, and if it finds that the

first floor is fully filled , it goes to the second floor and thus the

procedure stops here. As soon as a car is placed in a particular floor, the

display counter at the ground floor increments as to indicate the floor

capacity has decreased by one. After the lift places the car in a particular

floor, it comes back to its normal position and that time, the motor that

drives it , also stops. Now processor sends signal to glow GREEN LED indicating

that lift is free.

When a person needs to come down from a

particular floor to ground floor, he is expected to focus the headlight onto

the LDR placed in that floor. Now sensor section sends signal to motor that the

lift has to be send back to that particular floor and sends a signal to glow

RED LED indicating that the lift is busy. As soon as the lift reaches that

particular floor car should come inside the lift, the display counter at the

ground floor decrements by one as to indicate the floor capacity has increased

by one. Lift comes back to its normal position and that time, the motor that

drives it, also stops. Now processor sends signal to glow GREEN LED indicating

that lift is free.

If there no parking taking place, the processor

carries out the job according to the following priority:-

1.

It checks whether any

password is entered.

2.

It checks whether any

car is entered to lift.

3.

It checks whether any

car headlight is pressed in front of LDR placed in each floor.

It is like a round robin system.

Saturday, 24 November 2012

Wireless Station Intimation System

Our project demonstrate one such example were Radio Wave is employed in a way which is helpful to us.This project is designed and developed for helping the passengers traveling in train and bus especially during night. The people who are not aware of the station on which one should get down will find this very helpful.Here the station name is displayed and announced simultaneously when the station is about to reach which can assist both literate and illiterate.

The RF technology is used in the project to communicate between the transmitter and receiver. Each transmitter has a unique binary code which is transmitted continuously to space in a particular range. This signal is captured by the receiver when it reaches in its range. So in the case of a train, the transmitter placed in the station is detected by the receiver in the train and the binary code is

processed to give out the station name display and audio corresponding to the binary code in the receiver. A LCD unit is used for displaying the station name and a speaker is used for the announcement.

Main parts of this project are :

1. Power Supply

The power supply section is the section which provide +5V for the transmitter section to work. IC LM7805 is used for providing a constant power of +5V.

2. Encoder

This section contains the identity of the transmitter. An encoder can be a device used to change a signal (such as a bit stream) or data into a code. The code serves any of a number of purposes such as compressing

information for transmission or storage, encrypting or adding redundancies to the input code etc.

3. RF Transmitter

This section transmits the binary data to space in a particular range based on the antenna used. This signal is received by the receiver and it compares the binary code to find the corresponding station name from

the database.

1.1.2. Receiver

1. Power Supply

The power supply section is the section which provide +5V for the transmitter section to work. IC LM7805 is used for providing a constant power of +5V.

2. Decoder

A decoder is a device which does the reverse of the encoder, undoing the encoding so that the original information can be retrieved.

3. Microcontroller

Unlike microprocessors, microcontrollers are generally optimized for specific applications. As a result the peripherals can be simplified and reduced which cuts down the production cost.

4. RF Receiver

The RF signal transmitted by the transmitter is detected and received by this section of the receiver. This binary encoder data is sent to the decoder for decoding the original data.

5. LCD

This is the output unit in the receiver section. The station name is displayed on this display unit when the receiver comes in the range of the transmitter.

6. Voice Alert

This is another output unit in the receiver. This gives the voice alert of the station reached based on the RF transmitter signal received.Voice recording ic APR9600 is used here.

Wednesday, 29 August 2012

Traffic Light Controller

The circuit is made using AT89s2051 or can be replcad by 89s51.In this sequence of coloured lights:

- Illumination of the green light allows traffic to proceed in the direction denoted,

- Illumination of the yellow light denoting, if safe to do so, prepare to stop short of the intersection, and

- Illumination of the red signal prohibits any traffic from proceeding.

Tuesday, 28 August 2012

Joule Thief Circuit

Joule thief is a nickname for a minimalist self-oscillating voltage booster

that is small, low-cost, and easy-to-build; typically used for driving

light loads. It can use nearly all of the energy in a single-cell electric battery,

even far below the voltage where other circuits consider the battery

fully discharged (or "dead"). Hence the name suggests the notion that

the circuit is stealing energy or "Joules" from the source

The circuit uses the self-oscillating properties of the blocking oscillator, to form an unregulated voltage boost converter. As with all power conversion technology, no energy is actually created by the circuit. Instead, the output voltage is increased at the expense of higher current draw on the input. As a result, the amount of power entering the circuit is the same as the amount leaving, minus the losses in the conversion process.

The circuit uses the self-oscillating properties of the blocking oscillator, to form an unregulated voltage boost converter. As with all power conversion technology, no energy is actually created by the circuit. Instead, the output voltage is increased at the expense of higher current draw on the input. As a result, the amount of power entering the circuit is the same as the amount leaving, minus the losses in the conversion process.

Clap Switch

Here’s

a clap switch free from false triggering. To turn on/off any appliance,

you just have to clap twice. The circuit changes its output state only

when you clap twice within the set time period. Here, you’ve to clap

within 3 seconds.

T=1.1R7.C3 seconds

The

clap sound sensed by condenser microphone is amplified by transistor

T1. The amplified signal provides negative pulse to pin 2 of IC1 and

IC2, triggering both the ICs. IC1, commonly used as a timer, is wired

here as a monostable multivibrator. Trigging of IC1 causes pin 3 to go

high and it remains high for a certain time period C3. This ‘on’ time

(T) of IC1 can be calculated using the following relationship:

T=1.1R7.C3 seconds

where

R7 is in ohms and C3 in microfarads. On first clap, output pin 3 of IC1

goes high and remains in this standby position for the preset time.

Also, LED1 glows for this period The output of IC1 provides supply

voltage to IC2 at its pins 8 and 4. Now IC2 is ready to receive the

triggering signal. Resistor R10 and capacitor C7 connected to pin 4 of

IC2 prevent false triggering when IC1 provides the supply voltage to IC2

at first clap.

On

second clap, a negative pulse triggers IC2 and its output pin 3 goes

high for a time period depending on R9 and C5. This provides a positive

pulse at clock pin 14 of decade counter IC 4017 (IC3). Decade counter

IC3 is wired here as a bistable.

Each pulse applied at clock pin 14 changes the output state at pin 2 (Q1) of IC3 because Q2 is connected to reset pin 15. The high output at pin 2 drives transistor T2 and also energises relay RL1. LED2 indicates activation of relay RL1 and on/off status of the appliance. A free-wheeling diode (D1) prevents damage of T2 when relay de-energises

A very simple IR remote control switch for an electrical appliance

This project describes a technique of adding the remote control feature to an electrical appliance. The goal is to construct a black box where you can plug-in your 240V AC appliance and control the ON and OFF operations with a ir remote.The good thing about this project is that it does not use any microcontroller and is only based on the CD4017 decade counter IC.

Microcontroller-Based Solar Charger

As

the sources of conventional energy deplete day by day, resorting to

alternative sources of energy like solar and wind energy has become need

of the hour.

In the solar-powered lighting system, the solar charge controller plays an important role as the system’soverall success depends mainly on it. It is considered as an indispensable link between the solar panel, battery and load.

The microcontroller-based solar charge controller described here has the following features:

Solar-powered

lighting systems are already available in rural as well as urban areas.

These include solar lanterns, solar home lighting systems, solar

streetlights, solar garden lights and solar power packs. All of them

consist of four components: solar photovoltaic module, rechargeable

battery, solar charge controller and load.

In the solar-powered lighting system, the solar charge controller plays an important role as the system’soverall success depends mainly on it. It is considered as an indispensable link between the solar panel, battery and load.

The microcontroller-based solar charge controller described here has the following features:

- Automatic dusk-to-dawn operation of the load.

- Built-in digital voltmeter (0V-20V range)

- Parallel- or shunt-type regulation

- Overcharge protection

- System status display on LCD

- Deep-discharge protection

- Low battery lock

- Charging current changes to ‘pulsed’ at full charge

- Low current consumption

- Highly efficient design based on microcontroller

- Suitable for 10-40W solar panels for 10A load

courtesy:electronics4you

Wednesday, 29 February 2012

Friday, 10 February 2012

Displaying numbers on seven segment for begineers

A seven-segment display (SSD), or seven-segment indicator, is a form of electronic display device for displaying decimalnumerals that is an alternative to the more complex dot-matrix displays. Seven-segment displays are widely used in digital clocks, electronic meters, and other electronic devices for displaying numerical information.

A seven segment display, as its name indicates, is composed of seven elements. Individually on or off, they can be combined to produce simplified representations of the arabic numerals. Often the seven segments are arranged in an oblique (slanted) arrangement, which aids readability. In most applications, the seven segments are of nearly uniform shape and size (usually elongated hexagons, though trapezoids and rectangles can also be used), though in the case of adding machines, the vertical segments are longer and more oddly shaped at the ends in an effort to further enhance readability.

Each of the numbers 0, 6, 7 and 9 may be represented by two or more different glyphs on seven-segment displays.

here is a circuit which shows the interfacing of a seven segment with 8051 microcontroller and displays the numbers from 0 to 7.The numbers on the seven segment can be controlled by the port 1 buttons.

Download file for 89s52:

https://rapidshare.com/files/4150646605/sevensegment.zip

Friday, 13 January 2012

TEXT DISPLAY ON LCD USING 89S51/52 MICROCONTROLLER

Video showing the characters displayed on lcd using 89s52

A static message can be displayed on a 16x2 LCD by interfacing it to the microcontroller (AT89C51). The same message can also be displayed with certain animated effects like moving, blinking etc. This topic explains how to create dynamic effects with the text displayed in LCD.A string or message can be displaced on LCD by sending its characters to data register after configuring the command register of LCD. To create dynamic effects, a specific command instruction is sent to LCD via microcontroller AT89C51. The different command codes for LCD are tabulated below:

A static message can be displayed on a 16x2 LCD by interfacing it to the microcontroller (AT89C51). The same message can also be displayed with certain animated effects like moving, blinking etc. This topic explains how to create dynamic effects with the text displayed in LCD.A string or message can be displaced on LCD by sending its characters to data register after configuring the command register of LCD. To create dynamic effects, a specific command instruction is sent to LCD via microcontroller AT89C51. The different command codes for LCD are tabulated below:

Hex Code

|

Command to LCD Instruction Register

|

1

|

Clear screen display

|

2

|

Return home

|

4

|

Decrement cursor

|

6

|

Increment cursor

|

5

|

Shift display right

|

7

|

Shift display left

|

8

|

Display OFF, cursor OFF

|

A

|

Display OFF, cursor ON

|

C

|

Display ON, cursor OFF

|

E

|

Display ON, cursor blinking

|

10

|

Shift cursor position to left

|

14

|

Shift cursor position to right

|

18

|

Shift the entire display to the left

|

1C

|

Shift the entire display to the right

|

80

|

Force the cursor to the beginning of the 1st line

|

C0

|

Force cursor to the beginning of the 2nd line

|

38

|

Use 2 lines and 5x7 matrix

|

courtsey : www.engineersgarage.com

Subscribe to:

Comments (Atom)